SERVICES

Services

Since its founding, E-PoC Crafter has continuously invested in both talent and equipment.

Today, we have established a comprehensive system that meets the needs of all our customers. From a wide range of prototyping and manufacturing techniques, we select the most suitable solutions tailored to each project — from prototype to mass production.

We provide expert recommendations on the most appropriate technologies and processes, enabling even very small-lot production with high efficiency.

Our one-stop service covers the entire journey: from concept and 3D data creation, to prototype validation and mass production.

Design Support

- 3D Scanning

- Industrial Design

- Mechanical Design

- CMF Verification (Color, Material, Finish)

- Mass Production Evaluation

Mechanical

Processing

- CNC Machining

- Lathe Machining

- Wire Cutting

- EDM (Electrical Discharge Machining)

- Stamping

- Bending

- Welding

Molding

Technology

- 3D Printing

- Vacuum Casting

- Low-Pressure Injection Molding

- Rapid Injection Molding

- Sheet Metal Fabrication

Surface

treatment

- Painting

- Anodizing

- Electroplating

- Leather Treatment

- Laser Engraving

- Silk Screen Printing

- Assembly

Techniques

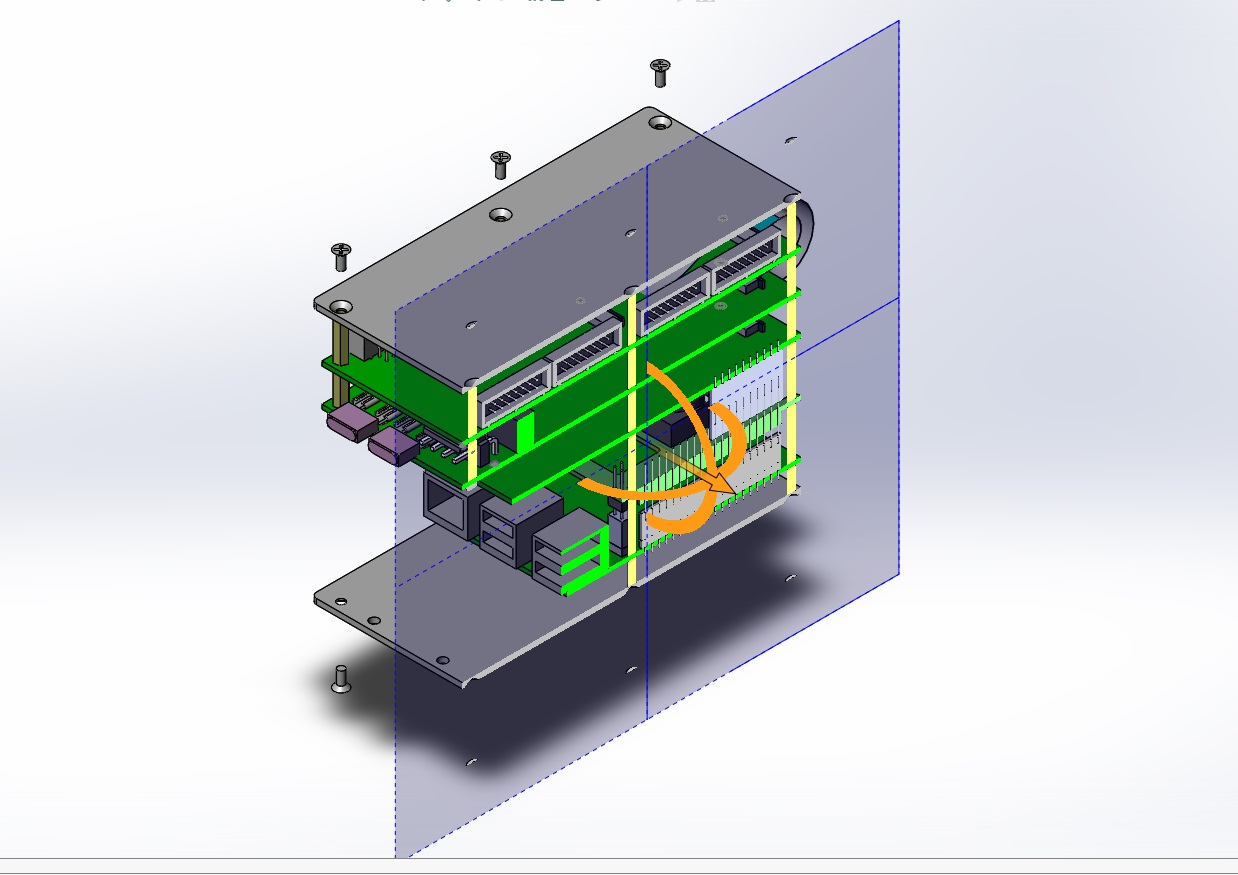

3D Scanning/Industrial Design/Mechanical Desigh

At E-PoC Crafter, We don't just manufacture — we help you build better products from the very beginning.

We offer comprehensive design support services to accelerate your product development cycle, including:

3D Scanning,Industrial Design,Mechanical/Structural Design

We work with all major CAD formats such as UG (NX), Creo, SolidWorks, and more, making it easy to collaborate seamlessly with your team.

Whether you're starting with a rough idea or refining an existing prototype, we help you:

Optimize functionality,Improve manufacturability,Bridge the gap between concept and production

Let us turn your ideas into reality — faster, smarter, and with precision.

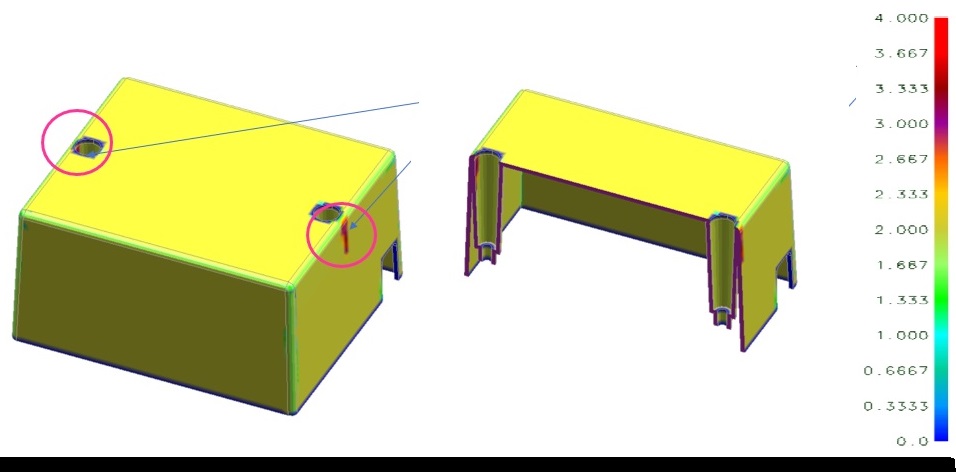

CMF Verfication/Mass Production/ Small batch production

At E-PoC Crafter, we provide a full range of design and production support services to help you take your product from concept to mass production with speed, flexibility, and precision.

We offer CMF verification, where we provide samples of materials and surface treatments, as well as 3D texture references, allowing you to visualize and select the best options for your product's color, material, and finish. We’ll also guide you through the advantages and disadvantages of each choice to help you make more informed decisions.

For small batch production, we offer flexible, fast, and cost-effective solutions that are ideal for pre-production testing, pilot runs, and market validation. Whether you are moving from prototype to production, we ensure that small batch parts meet the same high quality standards as mass production.

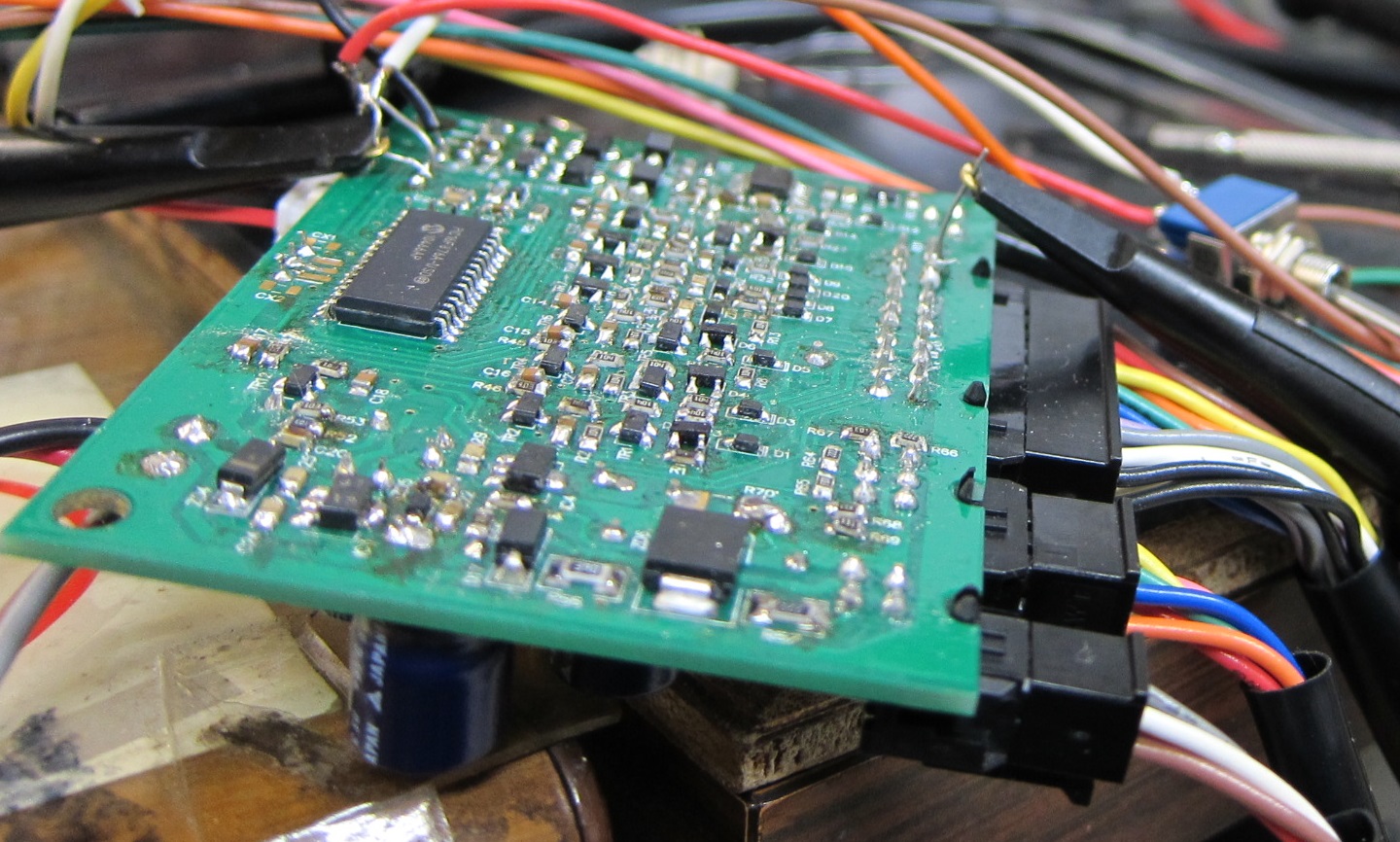

For mass production, we help you scale up smoothly by recommending the most suitable materials that balance cost and performance, providing injection molding flow analysis, and ensuring high-quality assembly with trusted partners. We also handle PCBA and can deliver working mockups, ensuring your product is ready for the market.

3D Printing

At E-PoC Crafter, we offer high-quality 3D printing services for both plastic and metal parts. Whether it's small-batch prototypes or complex structural components, we can meet our customers' needs. We support a variety of materials, ensuring precision and excellent surface quality. Our 3D printing equipment has a maximum build size of 1 meter, enabling us to handle everything from intricate small parts to larger components.

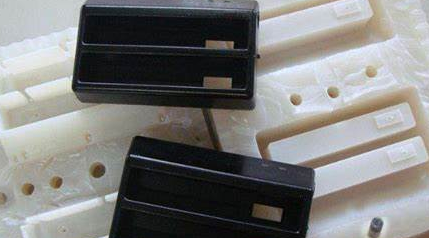

Vacuum Casting/Low -Pressure Injection Moliding

At E-PoC Crafter, we specialize in Vacuum Casting and Low-Pressure Injection Molding, offering high-quality prototype production and small-batch manufacturing services for everything from precision small parts to large components. We can deliver prototypes in as fast as 3 days, serving industries such as home appliances, automotive, medical, and aerospace. Our products can reach a maximum size of 2m x 1.2m x 1m, and we cater to various needs, including precision structural parts, complex 3D geometries, transparent components, and large-scale products. We provide high-precision samples, excellent surface quality, and dimensional accuracy, ensuring fast delivery and meeting diverse production requirements.

Vacuum Casting: Ideal for producing high-precision prototypes with excellent detail, with material properties that closely resemble final production parts.

Low-Pressure Injection Molding: Best suited for small to medium batch production, providing excellent surface quality and dimensional accuracy.

- 2 sets of RIM low-pressure injection machines

- 2 machines

- 5 sets of vacuum casting machines

- 5 machines

- Materials

- ABS, PP, POM, PC, PMMA, TPU, Silicone, etc.

- Precision

- ±0.20mm/100mm (±0.0079in/100in)

(±0.2mm within a 100mm length range) - Recommended Thickness

- 3mm (0.12in)

(Max: 10mm / 0.39in / Min: 1.5mm / 0.059in) - Maximum Processing Size

- 2000mm x 1200mm x 1000mm (78.74in x 47.24in x 39.37in)

- Maximum Processing Weight

- 10kg (22.05lbs)

Plastic Parts CNC Machining

Precision Plastic Machining – From Prototype to Production

We specialize in high-precision plastic machining, operating 24/7 to ensure speed, accuracy, and consistency for your plastic components.

1, 80+ CNC Machines – Advanced 3-axis to 5-axis machining for ultimate flexibility.

2, Wide Material Range – Expertise in ABS, PC, ABS+PC, PMMA, PA, POM, PBT, PEEK, PPS, and Bakelite, including +GF (Glass Fiber) and flame-retardant materials.

3, 24/7 Production – Ensuring fast turnaround and meeting tight deadlines.

From prototyping to small-batch production, we deliver top-tier plastic machining solutions tailored to your needs.

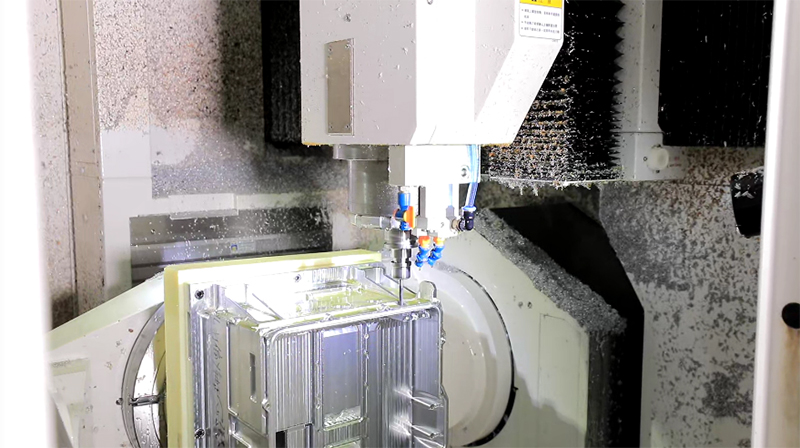

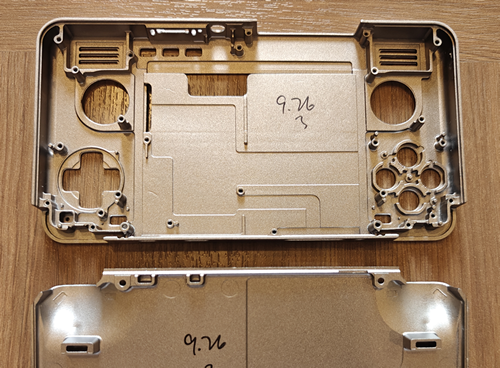

Metal Parts CNC Machining

Precision CNC Machining – From Prototype to Production

We specialize in high-precision CNC machining, operating 24/7 to ensure speed, accuracy, and consistency for your metal components.

1, 70+ CNC Machines – Advanced 3-axis to 5-axis machining for ultimate flexibility.

2, Wide Material Capability – Expertise in aluminum alloys, stainless steel, magnesium alloys, copper alloys, and steel.

3, Structural & Cosmetic Excellence – High-precision machining for both functional and cosmetic parts.

4, 24/7 Production – Ensuring fast turnaround and meeting tight deadlines.

From prototyping to small-batch production, we provide top-tier CNC machining solutions tailored to your needs.

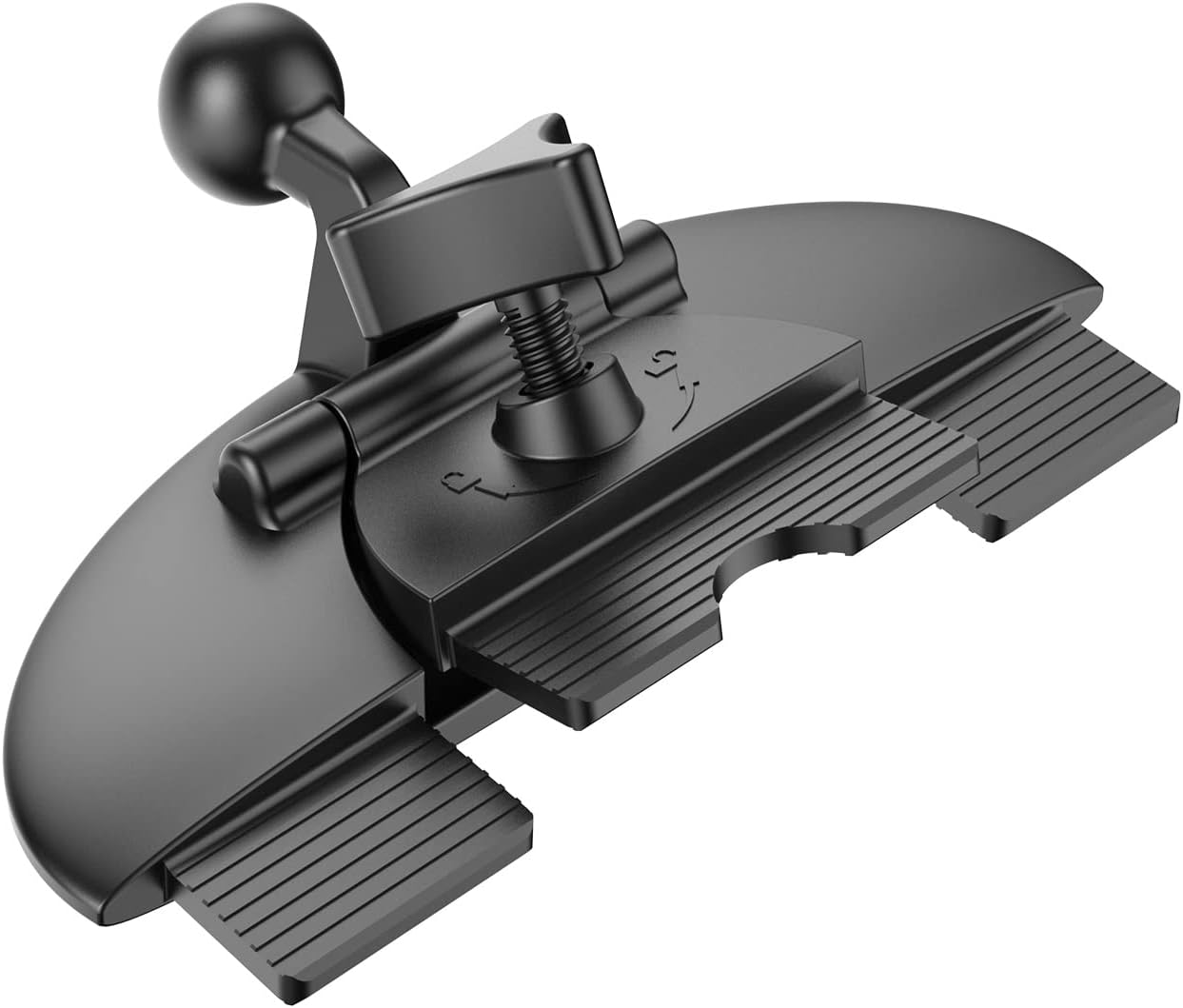

Sheet Metal Fabrication

We provide comprehensive precision sheet metal fabrication services, handling everything in-house for maximum efficiency and quality.

1, Advanced Equipment – From flat laser cutting, 5-axis laser cutting, hydraulic presses, bending machines, welding, riveting, to surface treatments, we cover it all.

2, Complex & Large-Scale Capabilities – Whether it’s simple bent parts or complex 3D automotive panels, we’ve got you covered.

3, Max Size: 2.5 m*2m – Capable of handling large-format components.

4, Fast Turnaround – Prototypes ready in as fast as 7 days.

Your one-stop solution for high-precision sheet metal parts!

Rapid Injection Molding

Rapid Injection Molding – Fast, Cost-Effective & Production-Ready

We provide rapid injection molding solutions that strike the perfect balance between speed, cost, and material accuracy, making it the ideal choice for product development validation and small-batch production.

1, 99%+ Close to Mass Production – Matches real production materials & processes.

2, 1/3 the Cost of Production Molds – High quality at a fraction of the price.

3, Samples in as Fast as 7 Days – Accelerate development & validation.

4, Perfect for Small Batches & Pre-Production – Ideal for low-volume orders & testing.

Painting / Anodizing / Electroplating / Leather Treatment / Laser Engraving / Silk Screen Printing / Assembly

We provide a comprehensive range of CMF (Color, Material, Finish) treatment solutions, delivering high-quality, customized surface finishes to meet your product requirements.

With state-of-the-art facilities and a highly skilled team, we ensure precision, consistency, and superior quality across automotive, medical, aerospace, consumer electronics, and industrial applications.

Materials

- Resin processing

- ABS/PC/POM/TPU/PA/PMMA/Bakelite, etc.

- Metal processing

- Aluminum/copper/stainless steel/iron/magnesium/titanium/zinc alloy, etc.

- Others

- Sponge/glass/wood, etc.